Contents

Engineering

See also: Physics, Chemical engineering, Biomedical engineering, Electrical engineering, Software.

Power law

- Preferential attachment or Matthew effect: “the rich get richer”.

- Pareto principle, Pareto distribution, or 80/20 rule: 20% of causes lead to 80% of consequences.

- Gibrat’s law: firms grow at a constant rate.

- Lindy effect: future life expectancy of a thing is proportional to its current age.

- Log normal distribution

- Zipf’s law: word frequency is inversely proportional to word rank.

- Lotka’s law: publication counts follow a power law.

- Benford’s law: the distribution of first digits is biased for numbers sampled from a power law distribution.

- Bradford’s law: in any field, a few core journals publish most of the relevant articles.

- Sturgeon’s law: “90% of anything is crap”.

- Participation inequality

- Silent majority: most people don’t participate in public discourse.

- 1% rule: only 1% of users in an Internet community post content.

Simplicity

- Brevity is the soul of wit -Shakespeare

- Simplify, simplify, simplify -Henry David Thoreau

- Perfection is reached not when there is nothing left to add, but when there is nothing left to take away -Antoine de Saint-Exupéry

- Less is more -Mies van der Rohe

- Worse is better.

- Perfect is the enemy of good.

- KISS (Keep it simple, stupid), Rule of least power, and YAGNI (You aren’t gonna need it)

- Occam’s razor or the principle of parsimony: the simplest explanation is most likely.

Scope creep

- Feature creep

- Inner platform effect: web browser and text editor extension platforms are often OS-like.

- Greenspun’s tenth rule: any sufficiently complicated C or Fortran program contains an ad hoc, informally-specified, bug-ridden, slow implementation of half of Common Lisp.

- Second system effect

- Zawinski’s Law: every program attempts to expand until it can read mail.

- Parkinson’s law: work expands to fit the time available.

- Not invented here (NIH)

History

Agricultural Age

- 6000 BC. Bow drills and drilled molar crowns at Mehrgarh in modern-day Pakistan near the Indus River.

- 3500 BC. Potter’s wheel in Sumer and the Indus Valley.

- 2300 BC. Sumerian abacus.

- 2613 BC. Egyptian measure slopes using the archipendulum combining a plumbline and a horizontal bar.

- 2000 BC. Sumer wooden plow, seed hopper, and tube.

- 2000 BC. Earliest quartz lenses in Crete.

- 1600 BC. Water clocks in Babylon, Egypt, and Persia. Also earliest sundials.

- 1400 BC. Roman use styli to write on reusable wax tablets (cerae), often in diptych format. Uluburun shipwreck.

- 1300 BC. Lathes in Ancient Egypt.

- 1200 BC. Babylonian star catalogues.

- 1000 BC. Austronesian and Polynesian develop long-distance maritime trade networks.

- 1000 BC. Rigveda describes using quadrants to measure a solar eclipse.

- Canals

- Ports

- 500 BC. Crop rotation in China: two-field and three-field system. 814 in Europe. Cereal crops, legumes to fix nitrogen, and fallow for grazing and fertilizer.

- 400 BC. Signaling via beacon fires along the Great Wall.

- 325 BC. Greek explorer Pytheas measures latitude from the height of the Sun above the horizon at midday.

- 206 BC. Han dynasty: lodestone compass, multi-tube seed drill, and iron plough.

- 150 BC. Astrolabe.

- 1391. A Treatise on the Astrolabe by Chaucer is an early technical manual.

- 40 BC. Han dynasty uses a water wheel-powered trip hammer to pound and decorticate grain.

- 25 BC. De architectura (Vitruvius) describes human-powered reverse overshot water wheels to remove water from mines.

- 8 BC. Papermaking by Cai Lun. Mulberry tree domesticated in 500 for paper.

- 125. Zhang Heng invents the complete armillary sphere, adding horizon and meridian rings to the ecliptic ring and fixed equatorial ring.

- 500. The horse collar increases horsepower by 50%. It allows the horse to push with its hindquarters, instead of pulling with its shoulders. The hames are two curved pieces of wood across the neck that sit on a padded collar and take the force of the pull. The traces or pulling straps connect the load to the hames.

- 593. Woodblock printing in China.

- 808. Gunpowder 火药 invented by Chinese alchemists. Mixes sulfur, saltpeter, and carbon.

- 900. Panemone windmill with a vertical axis of rotation used to pumping water in Persia.

- 1000. Spinning wheel in China, India, and Mesopotamia.

- 1092. Su Song builds an astronomical clock with an escapement and water wheel.

- 1100. Paper manufacture in Spain.

- 1185. Post windmill in England used to grind cereal. Also used in France and Flanders. Entire windmill body rotates to face the wind.

- 1400. Masonry tower mill: only the cap is rotated, so the structure and sails can be made taller.

- 1700. Smock mill replaces the masonry tower with the smock, a sloping wooden tower, horizontally weatherboarded, thatched, or shingled, usually octagonal.

- 1745. Windmill fantail automatically turns the cap into the wind. Patented in England.

- 1295. mariner’s astrolabe.

- 1594. Captain John Davis invents the Davis quadrant to measure solar elevation.

- 1701. Jethro Tull seed drill.

Scientific Revolution, 1500

- 1240. Ebstorf Map is a massive medieval map centered on Jerusalem with east on top. See also spatial analysis

- 1267. Opus Majus by Roger Bacon emphasizes empirical experimentation. First European work to describe gunpowder.

- 1300. Carta Pisana is the oldest surviving nautical chart, a portolan chart with rhumbline networks showing lines of constant bearing.

- 1300. Hereford Mappa Mundi is the largest surviving medieval map.

- 1328. Oxford Calculators state the mean speed theorem.

- 1350. Nicole Oresme proves the divergence of the harmonic series. Also proves the mean speed theorem.

- 1375. Catalan Atlas is a medieval map.

- 1439. Gutenberg printing press with movable type.

- 1450. Venetian Fra Mauro map was the most accurate map of the world.

- 1543. Heliocentric theory by Copernicus.

- 1551. Historia animalium by Conrad Gessner.

- 1564. Index Librorum Prohibitorum blacklists many Protestant scholars.

- 1580. Prosthaphaeresis (“great parallax”) uses cosine product formulas to estimate large multiplications: cos a cos b = 1/2 (cos(a+b) + cos(a-b)). Values were shifted to cosine range and looked up in inverse cosine table.

- 1614. John Napier invents the logarithm, soon used in the slide rule and earlier Napier bones.

- 1650. Vacuum pump by Otto von Guericke. He demonstrates two Magdeburg hemispheres that cannot be pulled apart by horses.

- 1656. Christiaan Huygens invents the pendulum clock. Much more accurate than spring-driven clocks with a verge escapement. Also invents the balance spring or hairspring in 1675 and the centrifugal governor for adjusting the gap between mill stones for grinding grain.

- 1660. Royal Society is the oldest academy of sciences.

- 1666. Isaac Newton discovers gravity. Principia Mathematica (1687) describes the laws of motion, including the conservation of momentum. He also invents the reflecting telescope and sextant.

- 1676. Hooke’s law: spring stiffness relates force and deformation.

- Francis Bacon writes on empiricism and the scientific method.

- 1759. John Smeaton optimizes the water wheel.

- 1820. First practical mechanical calculator, the Thomas Arithmometer.

- Artificio de Turriano. Water wheel drives oscillating tie-rod linkage, which power many stages of spoons to lift water.

- 1684 Water pump for the Palace of Versailles: 14 paddle wheels moving 800,000 gallons/day. Cost over 100 million present dollars.

Second Agricultural Revolution.

- Norfolk four-course crop rotation of wheat, turnips, barley, and clover instead of a fallow year. Turnips and clover are fodder crops for animals.

- 1650 The Chinese seed drill reduces wasted seed.

- 1730 The Chinese wheelless iron-tipped mouldboard plough can be pulled with one ox instead of six oxen previously.

- 1784 Threshing machine improves productivity.

- Robert Bakewell pioneers selective breeding of livestock.

1760 First Industrial Revolution mechanizes the British textile industry with water power. Europe transitions from cottage industry and the domestic workshop or putting-out system to urban factories.

- 1733 Flying shuttle double weaving efficiency, so eight spinners are now required per weaver.

- 1765 The water frame by Richard Arkwright mechanizes cotton spinning.

- 1765 Spinning jenny by James Hargreaves allows eight spindles to be operated together, but produces weaker cloth.

- 1779 Spinning mule by Samuel Crompton. Starts with 48 spindles and expands to 1,320 spindles.

- 1785 The power loom mechanizes weaving.

- 1793 Samuel Slater brings British textile trade secrets to America.

- 1793 Eli Whitney invents the cotton gin, making upland short cotton profitable and expanding slavery. He also invents the milling machine and promotes interchangeable parts for muskets.

- 1798 Fourdrinier paper machine uses continuous production.

- 1804 Jacquard loom is programmable using punched cards.

- 1830 Richard Roberts’ self-acting mule is fully automatic. Also invents the Roberts loom.

- 1870 Sewing machine is 5x more productive.

- https://en.wikipedia.org/wiki/Rapier_loom

- https://en.wikipedia.org/wiki/Textile_manufacture_during_the_British_Industrial_Revolution

- https://en.wikipedia.org/wiki/Timeline_of_clothing_and_textiles_technology

1780 Steam power

- 1761. John Harrison invents a practical marine chronometer with a bimetallic strip and caged roller bearings.

- 1780. Circular saw for lumber mills.

- 1781. The Watt steam engine allows factories to replace water wheels. It uses a separate condenser to avoid cooling the power cylinder, improving fuel efficiency form 0.5% to 2%. Built with John Wilkinson’s 1774 boring machine.

- 1790. Fully automated flour mill by Oliver Evans, who gets the third US patent. Continuous production using bucket elevators, horizontal Archimedean screws, conveyor belts, and rotating spreading rake.

- 1800. Henry Maudslay invents the first screw-cutting lathe, allowing standardized screw sizes and interchangeable parts. He also produces precise surface plates or master planes in sets of three.

- 1818. Milling machine uses rotary cutters to remove material.

- 1820. Macadam road uses crushed stone of specific size. Peak of turnpike trusts which collected tolls to maintain roads. National Road.

- 1824. Portland cement.

- 1825. First public railway using George Stephenson’s steam locomotive. Shipping costs cut to 1/20.

- 1835. Screw propeller by Francis Pettit Smith.

- 1891. Pop pop boat is a pulsed steam engine with no moving parts. Ejects water in pulses.

1856. Second Industrial Revolution: Steel and coal power, railways, and machine tools.

- 1818. Lehigh Coal is the first vertically integrated US company, including transport and manufacturing.

- 1837. John Deere invents the horse-pulled steel plow. Coulter or knife cuts a 7" groove ahead of the plowshare blade.

- 1828. The hot blast technique recycles heat from flue gas to air entering a blast furnace, increasing fuel efficiency for pig iron.

- 1853. Safety elevator by Elisha Otis demonstrated at the New York World’s Fair.

- 1856. The Bessemer process allows the mass-production of steel. Steel replaces iron for railways, decreasing the cost of shipping.

- 1857. The Cowper stove uses firebrick for regenerative heating, instead of using iron which caused stress fractures.

- 1857. The Siemens-Martin process or open-hearth furnace uses regenerative preheating of fuel and air for combustion. Used to produce steel in 1865. Easier to control, can take scrap metal, and produces less brittle steel due to less nitrogen.

- 1856. James Harrison develops the first practical vapor compression refrigeration system for breweries and meat packing.

- 1930. Thomas Midgley Jr. invents Freon, the first chlorofluorocarbon.

- 1879. Thomas Edison invents the lightbulb.

- 1885. Starley invents the modern bicycle. A chain-driven gear train and rear wheel drive replaces the penny farthing, which directly drives a large front wheel.

- 1868. Paternoster lift (“Our Father”) is a continuous chain of open two-person compartments that loop like rosary beads. Less safe than an elevator.

- 1890. Robert Gair invents the pre-cut paperboard box.

- 1899. Escalator.

- 1900. High speed steel is hard even when red hot. Cutting speeds increase from 200 ft/min to 1000 ft/min from 1935 to 1955.

- 1905. Glass bottle blowing machine cuts costs from $2 to $10 cents.

1908 Oil, automobiles, mass production, and the Machine Age.

- 1828. Europe builds on Chinese cable tool drilling for oil wells.

- 1850. James Young refines crude oil.

- 1859. Edwin Drake drills Pennsylvania’s first oil well. He motorizes drilling techniques from Chinese laborers in the US.

- 1876. Otto internal combustion engine.

- 1916. Thomas Midgley Jr. develops leaded gasoline to prevent engine knocking.

- “an instinct for the regrettable that was almost uncanny” -Bill Bryson

- 1916. Thomas Midgley Jr. develops leaded gasoline to prevent engine knocking.

- 1908. William D’Arcy finds oil in Iran.

- 1908. Continuous track. Benjamin Holt licenses the patent, which merges to Caterpillar in 1925.

- 1903. Henry Ford invents the assembly line for the Model T.

- 1903. First airplane. Orville and Wilbur Wright brothers fly the Kitty Hawk biplane for 850 ft.

- 1912. First diesel ship. Diesel is one-third of shipping by 1950.

- 1913. Burton process for thermal cracking heats crude oil and doubles gasoline output.

- 1913. The Lincoln Highway is the first car transcontinental highway. In 1919, Eisenhower travels on the two-month Transcontinental Motor Convoy.

- 1920. Reflection seismology.

- 1930. Rotary drilling.

- 1937. Pallets and forklifts.

- 1937. The Hindenburg zeppelin airship catches fire, killing 36 people and ending the airship era.

- 1952. The US army develops the modular Conex box (“container express”). Malcom McLean popularizes the intermodal shipping container in 1955. It can be lifted by crane using a container spreader with twistlocks that secure four corner castings.

- 1956. Interstate Highway System.

- 1974 Sears Tower is the world’s tallest. Sears catalog, department stores, and subsidiary brands including Kenmore appliances, Craftsman tools, and DieHard batteries.

1940 Green Revolution or Third Agricultural Revolution.

- 1908 George Harrison Shull discovers hybrid vigor or heterosis.

- 1939 DDT organochlorine pesticide developed by Paul Mueller to control malaria.

- 1938 Organophosphates. Sarin nerve gas. Acephate (1973) controls aphids and ants.

- 1974 Glyphosate (RoundUp) kills broadleaf forbs and grasses. Phosphonate and EPSP inhibitor.

- 1950 Integrated pest management

- 2000 Indoxacarb kills caterpillars and moth larva as a sodium channel blocker. Banned in the EU in 2021 due to risk to bees and consumer risk.

- 1944 Cotton picker by International Harvester. Uses spinning barbed spindles remove seed-cotton, counter-rotating doffer moves the seed-cotton to the basket. Modern machines harvest up to 8 rows at 5 mph and cost $1M.

- 1972. The cotton module builder compacts cotton into 10-ton modules.

- A cotton stripper also removes plant matter like unopened bolls, the seed-bearing capsules, which it then separates and drops.

- 1944 Norman Borlaug breeds high-yielding varieties of dwarf wheat in Mexico resistant to stem rust. He runs a double breeding season in the central highlands and the north. Dwarf wheat supports larger and more numerous seed heads.

- 1964 M. S. Swaminathan popularizes Borlaug’s wheat in India, allowing India to become self-sufficient.

- 1966 Masagana 99 by Philippine President Ferdinand Marcos develops the IR8 miracle rice with 2x yield.

- 1970 Yuan Longping breeds hybrid rice after the Great Chinese Famine.

- 1960 High-yielding varieties of wheat and rice.

- 1987 Ice-minus bacteria or Frostban was the first GMO, treating bacteria-caused frost damage.

- 1990 French Jesuit Laulanie develops System of Rice Intensification in Madagascar, focusing on reduced water use, organic fertilizer, and careful planting of very young seedlings.

- 2000 Brazil becomes the second-largest soybean exporter and the biggest beef and poultry exporter after spreading 20 million tons of lime per year to neutralize its acidic inland cerrado region.

- Chemical fertilizer

- Mechanization

- 1927. Flash freezing leads to more nucleation sites, smaller ice crystals, and less cell wall damage. Ice crystals only form between 31 and 25 F. Clarence Birdseye.

- individually quick frozen (IQF): conveyor belt into blast chiller.

- Sway picking head moves the entire plant side to side. Orbit rotor uses many vibrating sticks to shake out the plant.

- Spring-loaded fan-shaped plates to catch fruit.

- Air stream rejects leaves and debris.

- side guard belt reduces rubbing

- 1927. Flash freezing leads to more nucleation sites, smaller ice crystals, and less cell wall damage. Ice crystals only form between 31 and 25 F. Clarence Birdseye.

- Sustainable agriculture and organic farming

- Masanobu Fukuoka: The One-Straw Revolution (1975). Pioneers no-till farming.

- Mulching retains soil moisture and prevents weeds.

- Carbon-to-nitrogen ratio: marine sediment has C/N ratio < 10:1. Algae have more protein, while vascular plants have cellulose.

- 1946 Lady Eve Balfour founds the Soil Association.

- Conservation tillage or strip tillage provides habitat and reduces erosion.

- Forestry and silviculture. Tree planting can sequester carbon.

- Guerrilla gardening and seed balls.

- https://en.wikipedia.org/wiki/Outline_of_sustainability

1980 Information Age, Third Industrial Revolution, or Digital Revolution. Knowledge workers, cognitive-cultural economy, new service-based economy.

Printing

- imposition arranges pages on the printer’s sheet.

- Hot metal typesetting

- Stereotype is a solid plate of type metal

- Linotype machine assembles a line of type which is cast into a sort or slug

- Electrotyping

- offset printing

- four CMYK plates via computer to plate (CTP)

- trapping requirements: overprints, choke, spreads and knockouts

- phototypesetting

- Folding

- Binding (saddle-stitch, hardcover) and trimming

- Publishing

- Copy editing

- Proofreading

- Modern

- Adobe InDesign

- preflight checks color profiles, bleed, registration, crop marks, spot colors, transparency flattening

- raster image processor rasterizes at 2400dpi

- input images at 300dpi due to halftone dithering for gradients and mixed colors.

- inkjet

- toner

- coil, wire, plastic comb binding

Microscopy

1595. Optical microscope.

- Condenser lens focuses light on the sample.

- Objective lens magnifies the collected image.

- Eyepiece or ocular lens further magnifies.

- Focus by moving the eyepiece nearer or further from the objective.

- Bright-field (BF) is simple for dark specimens. Otherwise staining is needed.

- 1621. Compound microscope by Cornelis Drebbel.

- 1665. Robert Hooke popularizes microscopy in Micrographia, the first book of microscope observations.

- 1876. Compound microscope with an oil immersion lens and a condenser by Robert Koch.

- 1893. Köhler illumination produces even illumination without an image of the light source (filament image), by ensuring that the light source is perfectly defosed, with the illumination light path passing parallel through the sample.

A dark-field microscope excludes the unscattered beam from the image. Increases contrast but requires stronger illumination. It uses a patch stop to exclude light that would be collected by the objective lens. A condenser lens focuses the remaining light on the sample.

Oil immersion: match the index of refraction of glass, 1.515, to increase numerical aperture. Otherwise some rays are lost.

1957. Confocal microscope by Marvin Minsky.

Interferometry

- Optical coherence tomography (OCT)

- 1995. Phase contrast microscopy. Frits Zernike, Nobel Prize 1953.

- differential interference contrast (DIC) microscopy

Super-resolution microscopy exceeds the diffraction limit.

1939. Electron microscope

- Ernst Ruska, 1986 Nobel Prize

- An electron gun, electron source, or emitter produces a collimated electron beam. A pointed tungsten or lanthanum hexaboride hot cathode.

- The anode is biased to a high voltage (1 kV) to accelerate electrons.

- A Wehnelt cylinder is an aperture which suppresses emission of electrons from most areas of the cathode. Often a platinum or tantalum foil at -200 V.

- A focused ion beam (FIB) uses ions instead of electrons.

- Cryo-EM. Jacques Dubochet, Joachim Frank, and Richard Henderson, 2017 Nobel Prize in Chemistry.

- A transmission electron microscope (TEM) sends a beam of electrons through a thin specimen, usually less than 100 nm.

- A scanning TEM (STEM) focuses the beam to 0.1 nm and scans it over the sample.

- Annular dark-field STEM imaging collects only scattered electrons. Sensitive to high angle, incoherently scattered electrons from nucleus Rutherford scattering. It is Z-contrast imaging since higher nucleus interactions increase scatter angles.

A scanning electron microscope (SEM) uses a beam of high-energy electrons.

- Large depth of field, though it only scans the surface so it requires destructive polishing to image multiple layers.

- A conductive surface creates a sharp picture. Evaporate a thin film of metal, 100 angstroms thick.

- Backscattered electrons (BSE) are high-energy. The BSE detector is a ring around the beam. Flat image. More sensitive.

- High-angle BSE (close to the beam axis) provides Z-contrast. T1 in the Thermo Trinity SEM.

- Secondary electrons are low-energy.

- Low-angle electrons (perpendicular to the beam axis) show surface toporgaphy or texture. Everhardt-Thornley detector (ETD) is typically low angle on the side.

- Conversion dynode amplifies ion signal by generating secondary electrons, which are accelerated to a microchannel plate (MCP).

Scanning probe microscopy

- atomic force microscopy (AFM) measures binding force.

- 1981. Scanning tunneling microscope. Gerd Binnig and Heinrich Rohrer, 1986 Nobel Prize.

Spectroscopy

1914. X-ray crystallography measures X-ray diffraction, which helps determine crystal structure. William Lawrence Bragg and his father William Henry Bragg, 1915 Nobel Prize.

1924. X-ray emission spectroscopy (XES): shoot a photon and measure the energy of the emitted photon. Penetrates a few micrometers.

1954. Electron spectroscopy: shoot a photon of known energy and measure the energy of the emitted electrons. The difference in energy is the binding energy. The electron structure is related to Z-number, oxidation state, bonding and coordination.

- X-ray photoelectron spectroscopy (XPS), by Kai Siegbahn. Half of the 1981 Nobel Prize. Surface only, 1-10 nm. High-power Kα source like Al (1486.6 eV) or Mg (1253.6 eV).

- 1977. Angle-resolved photoemission spectroscopy (ARPES) plots energy vs. emission angle, which provides more electronic band structure information.

- Energy-dispersive X-ray spectroscopy (EDS).

- Auger effect: removing a core electron causes a higher energy electron to fall into the vacancy. An Auger electron is a valence electron ejected by the released energy. Especially relevant in light atoms (Z<12).

- Auger electron spectroscopy fires X-rays or energetic electrons and measures the resulting spectra.

1960. Absorption spectroscopy measures absorption by wavelength.

- Near-Infrared Spectroscopy (NIR) targets overtone and combination vibrations of molecules, especially bonds involving hydrogen atoms.

- 1980. Used to identify contaminated food.

- Spectrophotometry measures concentration in terms of light absorption.

- 1937. Jahn-Teller effect of spontaneous symmetry breaking in spectroscopy.

- Mass spectrometry identifies molecules in a sample by measuring the mass-to-charge ratio of ions.

- Inductively coupled plasma mass spectrometry (ICP-MS) mainly detects metals. It uses an inductively coupled plasma to ionize the sample.

- Quadrupole mass analyzer separates ions based on the stability of their trajectories in the oscillating electric fields.

- 1937. Nuclear magnetic resonance (NMR) spectroscopy identifies organic molecules using an oscillating field. Excites atomic nuclei.

- Isidor Isaac Rabi, 1944 Nobel Prize.

- 1944. Electron paramagnetic resonance (EPR) or electron spin resonance (ESR) spectroscopy excites unpaired electrons.

- Muon spin spectroscopy (μSR) implants spin-polarized muons and detects atomic, molecular or crystalline influence on their spin. Requires a particle accelerator.

1960. Laser spectroscopy measures atomic energy levels. Nicolaas Bloembergen develops nonlinear optics by mixing beams of laser light to broaden its spectrum, and Arthur Schawlow develops two mirrors. Half of the 1981 Nobel Prize.

https://en.wikipedia.org/wiki/Template:Branches_of_spectroscopy

Isotope analysis

- Measured with isotope-ratio mass spectrometry (IRMS) or cavity ring-down spectroscopy (CRDS)

- Water has 150 ppm deuterium, 2000 ppm oxygen-18, and 400 ppm oxygen-17.

- Heavy water is D2O. It is 10% denser and has a melting point of 4 °C and boiling point of 101 °C.

- Doubly labeled water uses both deuterium and oxygen-18, which are stable and nonradioactive.

- delta-O-18 measures the difference in oxygen-18 concentration per thousand versus a standard.

- Rayleigh fractionation: heavier isotopes precipitate preferentially before reaching the poles, so ice sheets have lower oxygen-18 content. An increase in global temperature causes more ice sheets melting, decreasing ocean oxygen-18 and salinity. Ice core delta-oxygen-18 decreases by around half per thousand per °C. Ocean oxygen similarly affects calcite shells and limestone.

- Radiometric dating

- Radiocarbon dating determines the age of organic materials up to 60,

000 years using carbon-14, an unstable isotope. Living organisms have a relatively constant amount of carbon-14 due to continuous exchange with the environment, but once an organism dies, carbon-14 decays with a half-life of 6,000 years. - delta-C-13: −33 to −24‰ in C3 plants, and −16 to −10‰ in C4 plants. Mass extinctions decrease primary productivity, releasing plant carbon and causing a negative delta-C-13 anomaly. Positive excursions can be caused by reduced decomposition in anoxic ocean conditions.

- delta-N-15 increases with trophic level.

- uranium-lead dating

- Electron spin resonance dating

- Radiocarbon dating determines the age of organic materials up to 60,

Dating

- Stratigraphy

- Luminescence dating like optically stimulated luminescence (OSL) measures when minerals were last exposed to sunlight.

- Thermoluminescence dating and rehydroxylation dating of brick or pottery.

- Fission track dating records thermal history.

- Fluorine absorption dating: objects absorb fluoride ions from groundwater. Relatively low accuracy.

- Obsidian hydration dating (1960): hydration band grows at a known slow rate.

- Dendrochronology (tree-ring dating) and herbchronology.

Striking a fire striker with a flint or hard rock chips off very hot steel particles due to friction. Fire steel is soft due to high carbon content.

Dakota fire hole: fire pit where an upwind airway brings a draft for a hotter, more efficient fire with less smoke.

Mechanical engineering

https://en.wikipedia.org/wiki/Mechanism_(engineering)

https://en.wikipedia.org/wiki/Coupling

https://en.wikipedia.org/wiki/Bearing_(mechanical)

https://en.wikipedia.org/wiki/Outline_of_machines

A bolted joint can transfer tension or shear loads.

A planetary or epicyclic gear includes a central sun gear, planetary gears which orbit the sun, and an outer ring gear.

A kinematic pair is a connection that imposes kinematic constraints on relative movement.

- A lower pair has an area of contact.

- A revolute joint R allows rotation along a common axis, such as a doorknob.

- A prismatic joint P or slider allows linear sliding motion such as in a pneumatic cylinder.

- A cylindrical joint C allows rotation and translation.

- A universal joint U transmits rotary motion through rigid shafts at an angle. It uses a gimbal-like mechanism with two orthogonal hinges. Output speed is variable, causing vibration and wear.

- A spherical or ball joint S allows all rotations.

- A planar joint allows 2D translation and rotation in the plane.

- A four-bar linkage is the simplest closed-loop movable linkage. Ground is fixed in place. A crank is connected to ground by an R joint and can rotate fully. A rocker is grounded by an R joint and cannot rotate fully. A slider is grounded by a P joint.

- Quadrilateral linkage RRRR

- RRRP includes the slider-crank linkage.

- Doubler slider PRRP couples two sliders

- elliptical trammel of Archimedes

- Scotch yoke (slotted link) allows rotary control of valve actuators

- A higher pair has a point or line of contact, such as a ball bearing or a cam joint. Gear teeth mesh in cam joints.

The slider-crank linkage translates rotary and linear movement and comprises: crank (the rotating disc) - crankpin - (big end) connecting rod (small end) - crosshead - slider or piston rod - tube or cylinder. The crosshead bearing is constrained by crosshead guides to reduce sideways forces that cause friction and wear on the piston. The connecting rod small end has a needle sleeve bearing and wrist pin inside which fits into the crosshead, while its big end fits around the crankpin.

A ratchet restricts motion in one direction. It uses asymmetrical sloped teeth or a rubber surface and a spring-loaded pawl.

Socket wrench

- Lug wrench for removing wheel lug nuts.

A winch can store a dangerous amount of tension. A winch dampener slows down a a breaking cable.

In a bicycle, roller chain and sprockets transmit rotary motion between two shafts. The derailleur changes gears: cable tension moves a chain-guide between different sprockets. A gear hub shifts gears by driving different parts of planetary gears.

- Rim brakes apply friction pads to the wheel rim. Disc brakes squeeze hydraulic calipers against a rotor fixed to the wheel hub.

- The tire bead inflates and locks into a groove on the rim.

Industrial engineering

See also: Management.

Industrial engineering improves systems, processes, and organizations.

- https://en.wikipedia.org/wiki/Industrial_engineering

- https://en.wikipedia.org/wiki/Operations_research

- https://en.wikipedia.org/wiki/Supply_chain_management

- https://en.wikipedia.org/wiki/Template:Business_logistics

- https://en.wikipedia.org/wiki/Demand_forecasting

- Batch vs. flow production

Lean manufacturing or just-in-time

- Constant work in process (CONWIP) or pull-based production systems minimize inventory.

- value-stream mapping

- kanban scheduling

Japanese management culture

- Toyota Production System or The Toyota Way: long-term vision, production leveling or heijunka, nemawashi (consult with stakeholders), genchi genbutsu (leaders should “go and see” firsthand), and automated quality control. Develops lean manufacturing.

- Any employee can stop the process to signal a quality issue.

- Hansei: acknowledge mistakes and pledge improvement.

Continual improvement process or kaizen 改善: encourage workers to take ownership for their work.

- PDCA: plan, do, check, act cycle. Shewhart cycle, William Edwards Deming.

- Six Sigma: reduce process variation, sustained commitment to quality from entire organization.

- DMAIC: define, measure, analyze, improve, and control.

- Design For Six Sigma.

- 5S: keep the working area clear (整理), orderly, and clean. Order using shadow board, labels, and markings. Standardize processes. Training and audits.

- https://en.wikipedia.org/wiki/Six_Sigma#Tools_and_methods

- https://en.wikipedia.org/wiki/Seven_Basic_Tools_of_Quality

- https://en.wikipedia.org/wiki/Kaizen

- Peter principle: people rise to a level of incompetence.

- https://en.wikipedia.org/wiki/Conway%27s_law

- https://en.wikipedia.org/wiki/Seven_basic_tools_of_quality

- Cause-and-effect diagram

- Check sheet

- Control chart

- Histogram

- Pareto chart

- Scatter diagram

- Flowchart

https://en.wikipedia.org/wiki/Stochastic_processes

- https://en.wikipedia.org/wiki/Dynamical_system

- Percolation theory

- Hitting time

- Ergodic hypothesis: all accessible microstates are equiprobable in the long run.

- Measure-preserving dynamical system

- Poincaré recurrence theorem: systems eventually return to their initial state.

Failure analysis, reliability engineering, safety engineering

- A hazard is a source of harm.

- Verification and validation (V&V)

- Single point of failure (SPOF)

- Swiss cheese model

- Six Sigma

- Statistical process control (SPC)

- Risk matrix

- Probabilistic risk assessment (PRA)

- Failure mode and effects analysis

- Fault tree analysis

- Reliability block diagram or dependence diagram

- Event tree analysis explores responses to an event.

- Bow-tie diagram

- Engineering tolerance

- Mean time between failure (MTBF)

- Mean time to repair (MTTR)

- Failure mode and effects analysis (FMEA)

- https://en.wikipedia.org/wiki/Queueing_theory

- https://en.wikipedia.org/wiki/Fault_tolerance

- https://en.wikipedia.org/wiki/Stress_testing

- https://en.wikipedia.org/wiki/GxP

Ergonomics, human factors engineering, or engineering psychology

Machining

Industrial processes

- Web: paper, plastic film, foil, metal, textile, and wire

- Rolled as coils, packages and doffs.

- Coating: adhesive and silicone release liner

- Plating, laminating, slitting, and move via rollers

- Molding

- Blow molding

- Injection molding

- Extrusion molding

- Thermoforming plastic

- Vacuum forming plastic

- Surface finishing

- Packaging

- Machine tools

- A die cuts or forms material

- Stamping includes die cutting or clicking, punching, bending, blanking

- Hemming folds an edge over itself. Used in car manufacturing.

- Drawing dies

- Casting dies

- Stamping includes die cutting or clicking, punching, bending, blanking

- Using a drill bit to enlarge an existing hole, will catch at the sides (flutes) and bond, bend, or break. Tip working surface rendered useless.

- A die cuts or forms material

- https://en.wikipedia.org/wiki/Adhesive_bonding

- https://en.wikipedia.org/wiki/Process_engineering

Grinding

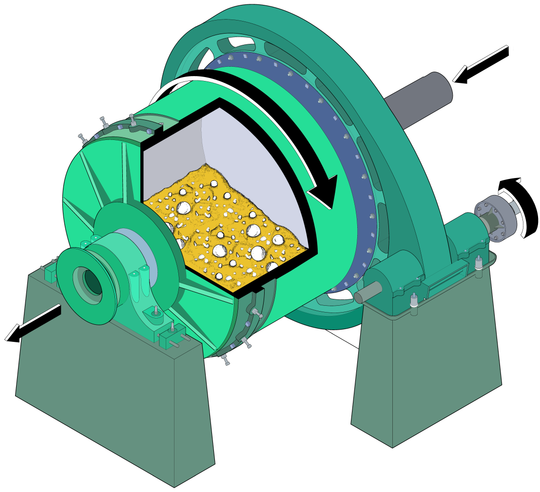

Ball mill grinder: steel or ceramic balls are lifted up then dropped. Simplest.

- Lined with manganese steel or rubber.

Lapping rubs surfaces with an abrasive. Brittle fracture leaves a rough surface with significant sub-surface damage. - 1456. Diamond scaife: polishing wheel with olive oil and diamond dust. Finish Ra < 1 nm with low damage. Shallow grooves.

Vertical roller mill produces a fine powder. More energy efficient but high maintenance cost.

https://en.wikipedia.org/wiki/Tumble_finishing polishes rough surfaces.

Engines

The internal combustion engine (ICE) takes in air, compresses it, ignites it, and releases it as exhaust.

A four-stroke reciprocating ICE or piston ICE: crankshaft rotates twice per cycle:

- Piston moves down and pulls air-fuel mixture into the cylinder.

- Piston moves up and compresses the gas.

- Piston moves down as fuel ignites.

- Piston moves up and releases gas as exhaust.

Gas piston engines use camshafts to open and close the throttle (intake valve).

- Two stroke diesel engine are up to 100,000 horsepower in ships, and 50% efficient.

- A tuned exhaust times a reflected high pressure wave to block the exhaust port to prevent loss of fresh intake. It then uses an expansion chamber to lower cylinder pressure to increase intake flow.

- Muffler reduces engine noise.

Engine Power = torque * angular velocity.

Angular velocity omega = 2pi * rps.

Power = W * rps / (rev/power stroke), where W = MEP * V_d.

MEP is the mean effective pressure of an engine design.

Displacement V_d = stroke length * cylinder area * number of cylinders.

A turbocharger uses exhaust gases to increase the density of fuel-air mixture in the engine, increasing power for a given displacement.

The Wankel engine is a niche internal combustion engine. The eccentric three-sided rotor compresses gas against an oblong housing. It is simpler, lighter, and smaller, but has lower thermal efficiency.

Jet engine

- Compressor or fan has many rotating blades and stationary stators or vanes which increase T and P.

- combustion chamber burns continuously

- Turbine extracts energy from the hot gases leaving the combustor. Series of bladed discs.

- Some of the energy spins the shaft to drive the compressor.

- Bleed air circulates in airholes to cool the turbine and combustion chamber walls.

- Afterburner reheats turbine exhaust gas to increase exhaust velocity. Much higher fuel consumption.

- Exhaust or nozzle. Subsonic nozzles are convergent.

- Auxiliary power unit (APU) gas turbine starts the compressor.

- A flame holder creates a low-speed eddy to prevent the flame from being blown out.

- Thrust reverser cups deflect thrust forwards to slow the aircraft and reduce wear on the wheel brakes.

- Specific impulse Isp measures how low the propellant can accelerate its own mass at 1 g: F_thrust = g * Isp * m’, where m’ is the mass flow rate (kg/s). For rockets, Isp = v/g for average exhaust speed v. Vacuum has higher exhaust speed due to lack of exterior pressure.

- Pulsejet uses cyclic pressure and subsonic deflagrations driven by acoustic resonance. Simple and light but has poor compression ratio and low specific impulse.

- Ramjet designed for Mach 2-5. It uses a shock cone to decelerate supersonic airflow entering the engine to subsonic speeds before combustion.

- Scramjet designed for Mach 5+. It maintains supersonic airflow throughout the engine. Combustion generates internal shockwaves for compression.

Rocket engine

- expander cycle: circulate cryogenic fuel through the nozzle and use it to drive the pumps. Limited to 300 kN of thrust. High Isp around 400 s in vacuum.

- pressure-fed engine: pressurized helium pressurizes the fuel and oxidizer tanks. Used for attitude control and orbital maneuvering thrusters. Heavier tanks.

- Space Shuttle orbiter spaceplane Reaction Control (RCS) and the Orbital Maneuvering (OMS) engines

- Apollo Command/Service Module RCS and Service Propulsion System (SPS) engines

- Apollo Lunar Module RCS, ascent and descent engines.

- SpaceX Falcon 1 upper stage Kestrel engine

- SpaceX Falcon 9: actuated grid fins.

- SpaceX SuperDraco (in-flight abort) and Draco (RCS) engines.

- SpaceX Starship is fully reusable, 100t LEO payload.

- Super Heavy booster has 33 engines in 3 rings.

- Starship spacecraft has 6 engines. 74,000 kN thrust.

- Raptor 3 engine, the first full flow staged combustion cycle. 3.6:1 LOX:CH4. 15° gimbaling range. Target $250k each. 280 ton thrust at sea level. 1,525 kg. Isp 350 s. Chamber pressure 350 bar.

- Integral plumbing, fuel cooling, and sensors with expensive 3D printing. Switches bolted flanges to welds. Removes the engine shroud.

- pump-fed engine

- Turbopump has an impeller. Pressure increases radially from the eye or inlet to the discharge.

- Slinger seal is a disc with blades or vanes that rotates with the shaft. It seals the shaft and impeller from outside low-pressure areas.

- Diffuser reduces fluid velocity and distributes pressure.

- Balance piston is designed to cancel out any pressure difference across the main components.

- Gas-generator cycle or open cycle. Gas generator (GG) or preburner powers the turbopump. Lowest specific impulse. 50k RPM, 2000 psi, many gallons per second. SpaceX Merlin engine.

- Staged combustion cycle or closed cycle. Fuel-rich preburner drives turbopumps. Requires a seal to separate fuel-rich gas from the oxidizer turbopump.

- Full-flow staged combustion uses oxidizer-rich and fuel-rich preburners to increase mass flow, allowing cooler and lower pressure turbines. Injects both propellants as gas, allowing higher pressure and greater efficiency.

- SpaceX Raptor engine.

- Turbopump has an impeller. Pressure increases radially from the eye or inlet to the discharge.

Thrust chamber assembly (TCA)

- injector

- showerhead injector is the simplest and least efficient

- impinging jet injector angles the fuel and oxidizer streams to collide. Manufacturing hundreds of holes, angles, and passages is expensive.

- pintle injector collide a cylindrical and a radial sheet.

- coaxial swirl injector: intake propellant with tangential velocity in a tube. Two cones collide with good atomization.

- Combustion Chamber

- Inconel is a nickel-chromium superalloy that is strong, heat tolerant, weldable, but with poor thermal conductivity. Softens at 1,200 °F.

- Combustion reaches 6,000 °F. Propellant circulates in channels to cool the chamber walls.

Cars

See also: heavy equipment

Powertrain

- automatic transmission

- the flexplate connects engine output to the torque converter. It can flex to account as rotational speeds change. It has gear teeth on its outer edge to couple with the starter motor.

- torque converter is a fluid coupling to transmit torque to the automatic gear train.

- manual transmission or gearbox

- the flywheel is powered by the crankshaft and smooths out jerky piston power. The flywheel connects to the clutch disc, which can disengage when shifting gears.

- a timing belt is a belt toothed with linear ridges to avoid slipping.

- circle slip clutch

- differential

- https://en.wikipedia.org/wiki/List_of_auto_parts

- The power take-off (PTO) transmits power from the engine to an application. It is often a splined (toothed) drive shaft.

- All wheel drive (AWD) uses an open differential. The open differential takes the path of least resistance and will give a slipping wheel all the power. A traction control system may cut power in response to slipping.

- Four-wheel drive (4WD) has a locking transmission so non-slipping wheels can have power. Designed for off-road.

https://en.wikipedia.org/wiki/Double_wishbone_suspension

Motorcycles often use a telescopic fork suspension. The triple clamps attach the fork tube, a spring-loaded hollow rod submerged in fork oil and air with holes for oil to squeeeze through. The tube sits inside a larger diameter aluminum slider, which connects to the wheel.

https://en.wikipedia.org/wiki/Original_equipment_manufacturer (OEM)

https://en.wikipedia.org/wiki/Automotive_electronics

Electronic control unit (ECU) or ECM

- engine control module (ECM)

- powertrain control module (PCM)

- body control module: windows, mirrors, door locks, immobilizer, air conditioning.

An event data recorder (EDR) logs steer angle, speed, throttle, brakes, anti-lock braking system (ABS), electronic stability control (ESC), engine RPM, seatbelt, airbag.

- An accident data recorder (ADR) logs crashes only. More limited in signals and logging time.

Advanced driver-assistance system (ADAS)

- adaptive cruise control (ACC) and lane centering or autosteer

- blind spot monitoring and lane change assistance

- parking sensors and surround-view system

- lane departure warning (LDW)

- forward collision warning (FCW)

- collision avoidance system (CAS)

- automatic emergency braking (AEB)

- electric vehicle warning sounds

- tire pressure monitoring

- automotive head-up display (HUD)

- self-driving: Ford BlueCruise and GM Super Cruise.

Gross vehicle weight rating (GVWR) is the maximum weight including cargo but excluding trailers.

Commercial driver’s license (CDL) needed to operate buses or heavy trucks.

- Headlamps are brighter on the driving side and softer on the opposite side to avoid blinding the opposite lane.

- https://en.wikipedia.org/wiki/Traffic#Rules_of_the_road

- https://en.wikipedia.org/wiki/Left-_and_right-hand_traffic

Trucking

- Tractor-trailor, semi-truck, eighteen-wheeler, or big rig.

- A tractor contains the engine, cabin, optional sleeper compartment behind the cabin, and fuel tanks on both sides.

- A class 8 truck is the largest class, with a GVWR over 33,000 lb.

- A 6x4 has a steering axle and two dual-wheel drive axles, or ten wheels total.

- An air dam above the cab reduces drag.

- Manufacturers: Volvo, Peterbilt, Daimler. Cummins engines.

- A semi-trailer is a trailer without a front axle.

- Often has tandem axles with dual wheels, or eight wheels total.

- A trailer skirt is a panel extending down from the side of the truck. It improves fuel efficiency by 5%.

- Attached via the fifth-wheel coupling. A 2" diameter kingpin at the front of the trailer couples with a horseshoe-shaped fifth wheel behind the tractor.

- 48’ or 53’ trailer holds 24 or 26 pallets.

- The federal weight limit is 80,000 pounds.

- Over-the-road (OTR) drives irregular routes: any place at any time.

- Owner-operator (O/O) is an independent contractor with a privately owned or leased truck. A company driver is an employee who drives company trucks.

- Full truckload (FTL) delivers an entire trailer to a single customer, while less-than-truckload (LTL) mixes freight from several customers.

- Package delivery: FedEx, UPS, and DHL.

Train event recorder: time, distance, speed, forward or reverse direction, throttle position, brake pipe pressure, independent brake, emergency brake, horn signal, headlights and marker lights.

https://en.wikipedia.org/wiki/Template:Rail_tracks

Boats

Knots

- A open loop, B closed loop, C single turn or single hitch where the legs cross over, D round turn

- Working end is used to make the knot. Standing end is the longer part.

- A bowline forms a reversible loop at the end of a rope.

- A hitch secures a rope to an object

- A clove hitch

- A single hitch is a turn tied around an object

- Half hitch: hitch where the rope is brought through the hole

- Cow hitch is symmetric. A pair of hitches where both ends of the rope go through the hole.

- A bend joins two lengths of rope

- Sheet bend can join lines of different diameter.

- https://en.wikipedia.org/wiki/Reef_knot

Ship directions are fore (front), port (left), starboard (right), and aft (rear). The bow and stern are the ends of the ship. Windward is upwind, where the wind is coming from, and lee is downwind.

Ship rotations include yaw (compass angle), pitch (front-to-back), and roll (side-to-side). The angle of list measure how much a ship heels (leans) to one side. Translations are surge, sway, and heave.

Sailing ships can have a foremast, main mast, and mizzenmast. The jib is a triangular sail ahead of the foremast.

Sailing rigs

- Yachts

- Catboat with a single sail

- Sloop with mainsail and jib

- Yawl with a small mast behind the steering post

- Ketch with a mizzenmast ahead of the steering post

- Working boats and coastal freighters

- Cutter with a single mast and multiple headsails

- Schooner with two or more masts

- Ocean-going merchant vessels

- Brig with two square-rigged masts

- Brigantine with square-rigged foremast and fore-and aft mizzen

- Barque with two square-rigged masts and a fore-and-aft mizzen

- Barquentine with one square-rigged mast and two fore-and-aft masts behind

- Full-rigged ship with three or more masts with square sails on each.

Maneuvers

- In a jibe, a ship reaching downwind turns its stern through the wind. Can be risky when the mainsail boom swings quickly.

- Beating to windward requires sailing at angles to the wind in zig zags, with tacking or coming about at the turns.

- crabbing is the angle difference between direction of motion and direction the ship points. crabs move sideways.

- conning

- go midship

- beam

- Navrules

- Vessel with right-of-way stands on course, while others give way.

- Commercial vessels restricted by draft or nets are privileged, and sailboats are privileged in crossings.

- Crossing course: let the vessel on the right pass in front.

- Head-on meeting: both steer right.

- Passing a boat in a river requires asking permission with two short blasts, which is granted with two short blasts.

Traditionally, sailing ships were commanded from the quarterdeck, a raised deck behind the main mast. The coxswain (or helmsman or steersman) would also stand here behind the wheel. This led to its use as the main ceremonial and reception area. Coxswain derives from cock and swain, meaning servant. Cockboat is an early type of ship’s boat.

The forecastle (“focsle”) is the deck in front of the foremast which houses the ordinary sailors’ living quarters. The aftercastle is structure behind the mizzenmast which consists of the afterdeck and poop cabin (from la poupe “stern”). The afterdeck or poop deck is the rear deck, which is raised in a sailing ship.

The bridge or wheelhouse is the command room of the ship. On paddle steamers, this was a walkway connecting the two paddle houses.

A cleat typically has two horns for securing ropes. A bollard is a post used to moor a boat. Bitts are paired posts for mooring. A capstan is a vertical axle to haul lines. A winch is a powered capstan. A windlass is a horizontal axle to let-out and heave-in equipment on lines.

- Capstan equation: a line wound around a capstan a total of ϕ degrees applies a force multiplier of exp(μϕ) for coefficient of friction μ.

- torque amplifier

The gunwale is the top edge of the hull. The bulwark is the nonstructural rail above the deck. The taffrail is the handrail around the stern. The strake timbers run from front to back. The garboard strakes are the two right next to the keel.

The stern post rests on or “fays to” the keel, and can be tilted or “raked” outward. The transom is the rear surface of the hull. It can also refer to the timbers that run side-to-side (“athwart”) from the stern post. The wing transom is the uppermost main transom, and the deck transom is the main transom level with the lower deck. The stern timbers rest or “step” vertically on the wing transom, and can rake further out. Above the wing transom is the counter and then window sill height. The stem is the forward post extending from the keel up to the gunwhale.

The skeg lines the bottom of the keel.

The draft or draught of the hull is the vertical distance between the waterline and the bottom of the hull (keel). Thus, it is the maximum depth of any part of the boat and determines the minimum depth of water the boat can navigate. The trim is the aft draft minus the forward draft.

The freeboard is the distance from the waterline to the upper deck, which determines the amount of reserve buoyancy remaining.

The waterline can also refer to the international load line, which is the highest waterline that the ship can legally be loaded to.

The length at the waterline (LWL) is smaller than the length overall (LOA).

The deadrise is the angle of the hull bottom: 0 for flat bottom boats, and up to 25 degrees on a deep-V hull. The sheer is how much the deck curves at each end. The sheer forward is usually twice the sheer aft. The camber is the lateral deck curvature, to allow water to wash off.

https://en.wikipedia.org/wiki/Sail_plan

https://en.wikipedia.org/wiki/Ship%27s_boat

The hull can sag if the beams bend down in the middle, and can hog if the beams deflect up in the middle. Shallow river boats were fitted with hog chains to avoid hogging from the heavy paddle wheels and boilers at the stern and bow.

In clinker planking, the hull planks overlap. From clinch, to fasten together. Carvel planking is laid flush, which is stronger.

flotsam and jetsam

“all at sea” means to feel confused or lost. A ship at sea in the 1700s is away from familiar landmarks.

“taken aback”: wind unexpectedly blows against the ship.

“go by the board”: thrown overboard

man-of-war

lugger

- A ship’s tender is a small boat carried as a shore transport or lifeboat.

- 1500 BC A galley is a long, slender ship with shallow draft and low freeboard, mainly rowed with oars facing backwards. (Narrower canoes must be paddled facing forwards, which is less efficient.) First used by Egypt, Greece, the Phoenicians, and later Rome. Around 1450, used by the Spain, Venice, and Ottomans. Mainly a coastal vessel since oar piercings would let in water in rougher seas.

- 332 BC Siege of Tyre. A Tyre fire ship destroys Macedonian siege towers.

- The Viking longship is a light, shallow-draft, clinker-built ship with oars and wool sails. It can be used for beach landings or carried over portages.

- The Viking knarr is an ocean-going cargo ship with a wider, deeper and shorter hull.

- 1100. A cog is an oak cargo and warship from 30 to 200 tons, with a few up to 1,000 tons.

- 1300. The carrack a carvel-built cargo and warship of Portuguese origin. Carries cannon on trucks (wood wheels) firing up to 32 pounds. The foremast and mainmast had square sails, which are better for sailing downwind. The stern mizzenmast is shorter and carried a lateen sail, which is better for sailing upwind.

- The caravel is an small agile Portuguese sailing ship of 100 tons.

- The fluyt is a Dutch oceangoing cargo ship of 200 tons. It has a shallow draft for river ports.

- 1600. Royal or first rank ships were 1000 tons, 50 guns, 400 men, 3 decks. Great ships or second rank had 40 guns, while middling or third rank had 30 guns. By 1800 a first rate ship had 100 guns. In 1778 the carronade was a short-barreled, short-range gun mounted on a slide. Half-pound swivel-mounted guns were not counted.

- A ship-of-the-line could stand in the line of battle, where ships would line up and fire broadsides.

- Age of Sail: 16th to 18th centuries.

- The galleon was a multi-decked Spanish cargo ship and the dominant warship. A sleeker carrack replacement, armed with cannons and a beak at the bow to ram other ships.

- Manila galleons sailed between Acapulco, Mexico and Manila. They were a part of the silver trade, bringing Filipino slaves, spices, and porcelain. They were the largest ships at 2,000 tons.

- The galleas blended the galleon and galley, with oars and cannons.

- The pinnace is a ship’s boat.

- 1583. The frigate was initially an agile full-rigged (three square sails) ship, first built by the Dutch in the Eighty Years’ War to combat Spanish Dunkirker privateers. Around 1850, the true frigate had only one armed deck. It was considered the second-smallest warship.

- 1700. The flyboat is an agile cargo carrier and privateering vessel. It displaced up to 200 tons and could carry a dozen cannon. Dutch vlieboot means a boat with a drought shallow enough to enter a river estuary.

The captain or master is responsible for safety and management. The chief mate or first officer is second in command. The second mate is customarily the navigator. The third mate is customarily the safety officer. Officers are licensed mariners.

An engineer or engine officer maintains the propulsion and support systems, including ship engine, fuel oil, lubrication, water distillation, separation process, lighting, air conditioning, and refrigeration.

A purser is responsible for money and administration, including supply, cargo and passenger manifests.

A pilot has specific knowledge of a dangerous or congested waterway, such as harbors, canals, and river mouths.

An able seaman is a seaman with more than two years of experience at sea.

Search-and-rescue (SAR)

- Emergency locator beacon or emergency position-indicating radiobeacon (EPIRB)

- Cospas-Sarsat: 406 MHz signal, 65 satellites. Computes location within 2 km via Doppler shift.

International Maritime Organization

- 1912. Titanic disaster leads to the SOLAS convention (Safety of Life at Sea).

- https://en.wikipedia.org/wiki/Template:Admiralty_law

Vessel traffic service (VTS) controls harbor traffic. Harbourmaster enforces safety and security regulations.

Notice to mariners (NOTMAR)

Marine radar: rotating X band or S band microwave beam. Ships reflect microwaves back to the antenna.

automatic identification system (AIS)

Electronic navigational chart (ENC)

Voyage data recorder: time, position, speed, gyro compass heading, radar,

Mapping and navigation

https://en.wikipedia.org/wiki/Map_projection

https://en.wikipedia.org/wiki/Stereographic_projection

https://en.wikipedia.org/wiki/Mercator_projection

https://en.wikipedia.org/wiki/Great_circle is the path of shortest distance.

https://en.wikipedia.org/wiki/Rhumb_line is a path of constant bearing.

Aerodynamics

An airfoil deflects air down, producing lift and drag forces.

- Camber asymmetry makes the top surface more curved.

- Sharp trailing edge.

- Flow separation: boundary layer slows down due to surface friction, causing higher pressure and an adverse pressure gradient. Flow separates when the speed of the boundary layer stops and reverses direction, detaching from the upper surface into turbulent eddies and vortices. Separation reduces the pressure differential that generates lift.

Flight control surfaces

- Empennage or tail assembly provides stability.

- Horizontal fins: elevator changes pitch and is mounted on the horizontal stabilizers, which maintain pitch or trim.

- Pulling back the elevator increases altitude until stall.

- Rudder controls yaw and is mounted on the vertical stabilizers which maintain yaw. Anti-balance tabs?

- Horizontal fins: elevator changes pitch and is mounted on the horizontal stabilizers, which maintain pitch or trim.

- Wing

- Trailing edge: ailerons and flaps change roll, turning the plane. Outboard aileron has a balance tab.

- Midwing: spoilers affect lift, drag, and roll. Ground spoilers are inboard, and the rest are flight spoilers.

- Canard: a small forewing forward of the main wing that increases maneuverability at high angles of attack.

- Trim tabs are small surfaces on the trailing edge of a larger control surface which function as servo tabs or balance tabs. These have a leverage advantage. The pilot moves the servo tab which is leveraged with a farter center of pressure. The servo tab deflects airflow and moves the control surface in the other direction, so on some aircraft the control surface is be free-floating. Stabilators (fully movable horizontal stabilizer) often have anti-trim tabs to decrease their sensitivity.

- Tail trim tank adjusts the center of gravity.

- FADEC: full authority digital engine control. Full control over engine start/restart, fuel flow, stator vane position, air bleed valve position. Ensures safety and efficiency. Tracks power (engine intake manifold pressure), RPM (measured by tachometer), altitude and air density, engine temp and pressure, etc.

- Propeller

- FADEC: one lever for throttle, fuel/air mixture, and propeller pitch.

- Manual fixed-pitch has a throttle (black) and a mixture control (red).

- Controllable-pitch or constant-speed propeller is more efficient. Uses a propeller pitch (blue) lever.

- Low pitch = low angle of attack = faster RPM = maximum power.

- Max continuous RPM is around 2,500 RPM for small planes.

- Prop feathering means zero pitch and no power. Improves glide ratio.

- Caused the Yeti Airlines 691 crash in 2023 in Nepal.

Helicopter

- Flight controls tilt the fixed lower swashplate.

- Rotating upper swashplate on the rotor mast uses pitch links to adjust the pitch of each blade cyclically as it spins.

- Aft cyclic tilts the swashplate to increase pitch. It can initiate autorotation. Cyclic also allows lateral tilt.

- With high forward airspeed, rapid aft cyclic increases load and causes rotor disc coning, where the rotor blades bend upwards, reducing lift surface.

- Raising the collective pitch or thrust lever raises the entire swashplate and increases the angle of attack of all rotor blades, generating more lift.

- Phase lag of a semi-rigid rotorhead in response to control forces is 90 degrees.

- Dissymmetry of lift: advancing blade produces more lift than the retreating blade. Blade flapping reduces the angle of attack of the advancing blade. Flapback tilts the rotor disc aft.

- Transverse flow effect: motion causes the rotor disc to roll to the side. A portion of the disc is in clean, unaccelerated air, while the rest is in descending air. Clean air sees a higher angle of attack and more lift, and phase lag results in a roll force.

High-lift device and boundary layer control

- Crucial for swept wings, where wing tip stall causes nose-up pitching moment.

- Leading-edge slats (outboard) and flaps (inboard) allow the aircraft to fly at lower speeds. They slide forward and allow air from below to flow in and energize the boundary layer.

- A leading-edge slot is fixed.

- A vortex generator is a vane that delays local flow separation. A turbulent boundary layer is less likely to separate than a slow, laminar boundary.

- A leading-edge extension (LEX) or root extension (LERX) or wing strake is a small triangular fillet between the root and fuselage. It generates a vortex on the upper surface at higher angles of attack.

- Wing fences are ribs on the ring that prevent the entire wing from stalling at once. Aligned with free stream airflow.

- A dogtooth extension or leading-edge cuff generates a vortex flow field to prevent separated flow from progressing outboard.

- A vortilon (vortex-generating pylon) is a flat plate under the plane aligned with the flight direction. Only for swept wings, which have span-wise flow at a high angle of attack. The vortilon diverts span-wise flow outwards, forming a vortex around the top surface which energizes the boundary layer.

- A stall strip is a 6" strip on the leading edge which undergoes intentional flow separation near a stall to improve handling.

- A turbulator is a thin zig-zag strip that creates turbulence.

- Boundary layer suction uses an air pump to remove the boundary layer.

Flight aerodynamics

- A stall is an angle of attack (AOA) above critical, causing flow separation. Nose tends to pitch down abruptly.

- The critical angle of attack, around 15°, produces maximum lift.

- Caused by excessive elevator or extending flaps.

- Lift coefficient (CI) vs. angle of attack (alpha) curve.

- Power off stall

- Mushing stall: the angle of attack is high enough to reduce lift, causing a high sink rate. But the tail still has airflow possibly from propeller wash or fuselage boundary layer influence, so the nose does not pitch down.

- Retreating blade stall. The retreating blade experiences a lower airspeed. To maintain equal lift across the rotor disc, the retreating blade needs a higher angle of attack, so it stalls first, causing pitch up and roll towards the retreating blade (usually the left side). Should not happen below VNE: Velocity Never Exceed.

- Stall speed: too slow means insufficient lift to maintain altitude. Maximum speed limited by the speed of sound, which decreases slowly with temperature. Exceeding the critical Mach number causes shock waves and flow separation from the wings. Aerodynamic ceiling or coffin corner is the where the two constraints meet.

- In a spin, the inside wing stalls while the outside wing does not, causing autorotation or uncommanded roll. Pulling back on the stick makes it worse.

- Erect spin: downward spiral. Easier to recover from since there is more airflow over control surfaces.

- Flat spin: nearly level attitude, so more dangerous. Can happen if the center of gravity is too far back. Recover with opposite rudder, in turn aileron, and forward stick.

- In a slip, the aircraft moves slightly sideways as well as forward relative to the oncoming airflow, which increases drag. The nose will point opposite to the bank of the wings.

- Coordinated flight has no slip and no perceived lateral acceleration. Turn and bank indicator ball in the center.

- Forward slip is used to reduce altitude without increasing speed. Changes the heading while maintaining the track.

- Crosswind landing: crabbing keeps wings level and nose pointing into the wind, balancing crosswind drag with engine thrust. Sideslip ailerons into the wind.

- A skid occurs when rudder is overapplied, causing slip to the other side. A skid can develop to a spin. (In a normal slip, the raised wing will stall first and reduce the bank angle.)

- A vortex ring state involves upward airflow through the inner rotor blades of a helicopter, causing a loss of lift.

Aerodynamic devices.

- The wing chord line is between the leading edge and trailing edge.

- The angle of incidence is between the chord line of the wing and the longitudinal axis of the fuselage.

- Washout: greater angle of incidence at the wing root so the root stalls first, providing more aileron control and less wing drop.

Air intake

Magnus effect. A spinning object experiences a lift force because it pulls boundary airflow in a preferred direction.

An intake ramp compresses supersonic air into the engine on a Concorde or an older fighter jet. It extends down from the top of a rectangular air intake so that the airflow converges and slows, increasing pressure. The ramp creates a shock wave where air abruptly slows down. The shock wave extends down towards the bottom lip, and its pitch angle decreases as Mach number increases. The ramp moves to angle the shock wave to meet the bottom lip, minimizing air spillage and pre-entry drag on the outer boundary of the deflected streamtube. However, the design requires heavy moving parts. Inside the intake, once the air is subsonic, a diverging ramp reduces speed and increases pressure even further.

Riblets, small grooves aligned with airflow, reduce skin friction drag by 2%.

An inlet cone controls supersonic ram compression for a circular air intake.

A splitter plate inside the intake diverts the boundary layer away from the engine intake.

A diverterless supersonic inlet uses a bump as a compression surface which prevents boundary layer air from entering.

Convergent-divergent de Laval nozzle for supersonic exhaust. Expansion to atmospheric pressure produces more thrust.

An engine bell redirects lateral components of exhaust momentum. As atmospheric pressure decreases, the exhaust plume tends to expand, reducing efficiency.

https://en.wikipedia.org/wiki/Rocket_engine_nozzle

Aerospike engine. An experimental rocket engine that maintains its aerodynamic efficiency across a wide range of altitudes. It is proposed for single-stage-to-orbit rockets. The design can be linear or toroidal.

Helicopter rotor

- Tip jet replaces the shaft drive. It places no torque on the airframe and does not need a tail rotor.

Aircraft

Aircraft components

- ram air turbine (RAT)

- flight data recorder

- Overwing engines are more difficult to service. Benefits include upper surface blowing which increases lift for STOL and have less debris damage.

Mach tuck. When airflow across a wing reaches supersonic speeds, a shockwave is produced.

Flight phases

- Startup

- Pushback from parking position at the airport gate to taxi position.

- Taxi

- Takeoff

- High-lift devices like slats and flats increase camber.

- V-speed

- beyond V1, takeoff should not be aborted.

- VR is rotation speed, when pilot begins to pitch up and leave the ground. 5°-15° is standard.

- V2 is the takeoff safety speed, where the aircraft can safely climb out with one engine out.

- Climb: VX maximizes angle of climb, and is slower than VY, which maximizes rate of climb. VX increases with altitude and VY decreases with altitude to converge at the absolute ceiling. Best angle of climb maximizes excess thrust and minimizes drag.

- Cruise altitude is 35,000 ft, and Mach 0.78 for narrowbodies and Mach 0.85 for widebodies. The maximum range speed minimizes drag. Speed for most economical operation adjusts for wind and cost index (time vs. fuel).

- Descent: for unpressurized aircraft, 10,000 ft is the maximum temporary safe altitude and 8,000 ft is the maximum safe altitude.

- Approach: from cruise to final approach.

- Missed approach: climb out from approach. Initiated at the decision height if the visual reference is not visible.

- Sterile cockpit rule: no non-pertinent conversation below 10,000 ft

- Traffic patterns are typically left-handed: aircraft descend counterclockwise.

- Short final approach

- 3° approach slope is standard.

- 1,000 ft is the stabilization gate

- on correct flight path, with only small inputs required to maintain it

- airspeed is 0-20 knots above landing reference speed

- airplane is in the landing configuration (e.g. landing gear down)

- rate of descent is below 1,000 feet per minute

- power setting is appropriate for the configuration (not at idle)

- checklists completed.

- Landing goes from short final to full stop. Landing gear down.

- Go around: climb out from final approach.

- Touch and go: touch the runway then climb out.

- Landing flare or round out raises the nose to slow the descent rate.

- Air Traffic Control (ATC)

- Visual Flight Rules (VFR)

- Instrument Flight Rules (IFR)

- Area navigation (RNAV) is specified in terms of waypoints.

- Performance-based navigation (PBN) uses navigation specifications and required navigation performance (RNP).

- Instrument landing system (ILS) provides short-range radio guidance until 200 ft altitude and 800 m distance.

- Localizer (110 MHz): horizontal guidance

- Glideslope (332 MHz): vertical guidance

- Broadcasts carrier and sidebands (CSB) with two modulating signals at 90 Hz and 150 Hz. Sideband-only (SBO) signal has a -90 degree phase shift on the left and +90 degree phase shift on the right. Information encoded as the difference in the depth of modulation.

- ground proximity warning system (GPWS)

- NOTAM (Notice to Air Missions) brief on hazards or temporary flight restrictions (TFR).

The North Atlantic Tracks optimize velocity to align with the jet stream. In America, most flights go west in the morning to chase the sun and east in the evening. Flights from US to Europe depart in the evening and land in the morning.

The Airbus A320neo is a narrow-body plane, 150’ long, 117’ span, 200 seats. Uses the CFM LEAP or Pratt & Whitney PW1000G high-bypass geared turbofan engine. Introduced in 2016 with 3,200 sold. Sharklet wingtip.

The Boeing 737 Max is a narrow-body plane, 140’ long, 117’ span, 180 seats. Introduced in 2017 with 1,400 sold. Split-tip winglet. A re-engine of the 737 where the larger 69" engines are mounted higher on the wings and further forward. This could lead to an excessive nose up angle. The Maneuvering Characteristics Augmentation System (MCAS) was introduced to mimic the flight behavior fo the 737, adjusting the horizontal stabilizer. However, it could activate continuously, could not be overriden by control column input, and did not warn or deactivate if the two angle-of-attack sensors disagreed. A faulted angle of attack sensor led the airplane to pitch down without pilot input, leading to a crash.

The Boeing 787 Dreamliner is a wide-body plane, 200’ long, 220’ span, 250 seats. Introduced in 2011 with 1,100 sold. It has raked wingtips, a four-window cockpit, and a smooth nose contour. It is bleedless, using electric pumps, actuators, compressors, and heaters. It is majority carbon fiber reinforced polymer, with aluminum leading edges and the titanium engines.

The Boeing 777 is a wide-body plane. It seats around 350 pax and was introduced 1995 with 1,700 sold.

The Airbus A380 was a double-deck wide-body quad-engine plane, 240’ long, 260’ wingspan. It ended production in 2020, $20B development cost, 250 sold, $445M price. Very large aircraft are no longer needed for a point-to-point system.

The Boeing 747 was the first wide-body plane, introduced in 1970. It ended production in 2023. It has four engines and seats around 360 pax.

Cessna 172 (1956) is the most produced aircraft with 40,000 built.

The Boeing Model 2 (1916) was Boeing’s first success. The Navy purchased 50 of the training seaplanes. Wong Tsu, Boeing’s first engineer, helps with wind tunnel testing.

Materials

- Materials: polyester, adhesive, silicone, foam, rubber, liner

- Amorphous

- Casting

- Corrosion

- Crystal

- Forensic materials

- Nanomaterials

- Surface

- Glasses

- Welding

Composites combine two materials, such as composite laminate. Advanced composite materials have a large volume of light, strong, stiff fibers in a weaker matrix. Polymer matrix composite, ceramic matrix composite, Metal matrix composite.

- Wattle and daub

- Papier-mache

Lubricants: graphite, polymer or oil-free lubricants

- Conversion coating prevents corrosion, lubricates, or improves adherence of other coatings.

- Phosphate conversion coating of steel uses phosphoric acid with manganese, iron, or zinc salt.

- Chromate conversion coating leaves an iridescent greenish-yellow tint. Cronak process (1933) is a 5 s soak in 182 g/L sodium dichromate and 6 mL/L sulfuric acid, which oxidizes Al and other metals and produces a hydrogel.

Natural materials

Wood

- Engineered wood

- Plywood: gluing wood at different angles gives better properties.

- Fibre saturation point: point with no free water, only water in cell walls, so that further drying results in shrinking and strengthening. Around 26% moisture content.

- Equilibrium moisture content increases with relative humidity.

Paper

- Wood contains:

- cellulose fibers: hardwood has short fibers for smoother and more uniform paper. Low-density softwood like fir has thinner, longer fibers for stronger paper.

- lignin: phenolic polymer that binds cellulose together, increasing rigidity. Acidifies, yellows, and breaks down paper. Newsprint has high lignin.

- hemicellulose: shorter branched carbohydrate polymers.

- Pulping converts wood chips into pulp (cellulose fibers)

- Mechanical pulping physically tears the fibers apart

- groundwood (GW) and refiner mechanical pulping (RMP)

- Kraft process uses white liquor, a hot mixture of sodium hydroxide and sodium sulfide, to break down lignin. Results in kraft paper, which is stronger without lignin, which interferes with cellulose hydrogen bonds.

- Durable paper is made from cotton and linen pulp.

- Mechanical pulping physically tears the fibers apart

- Bleaching removes lignin. Sodium hydroxide extraction and chlorine (or bleach before 1930). Chlorine free process uses oxygen and ozone. Hydrogen peroxide oxidizes color-causing non-aromatic conjugated groups. Sodium dithionite reduces color-causing groups.

- Kappa number measures lignin content using potassium permanganate, an oxidizing agent.

- Sizing increases water resistance so ink and paint stays on the surface. Waterleaf like blotting paper is unsized. Newsprint is slack-sized, while hard sized is most resistant. Internal sizing increases wet strength using alkyl ketene dimer (AKD) and alkenyl succinic anhydride (ASA).

- Acid-free paper adds calcium or magnesium bicarbonate to neutralize natural acids

- Paper size: A4 is 8.3x11.7“. Letter is 8.5x11”.

- Book size: octavo 6x9" is folded three times into 8 leaves or 16 pages. Quarto 9.5x12“. Folio 12x19”. Trimming and binding.

- Paper weight: Grammage (g/m^2). Basis weight is pounds (#) per ream of 500 sheets of uncut basis size. Letter size paper uses a 17x22" ream, while a 25x38" ream is used for octavo books.

- Paperboard is over 250 g/m^2 or over 0.30 mm thick. Higher stiffness.

- Folding boxboard is mechanical pulp between two layers of chemical pulp.

- Liquid packaging board is paper in between polyethylene and aluminum layers for milk and juiceboxes.

- Corrugated fiberboard is fluted in between linerboards.

- Corrugated fiberboard

Ceramics

- Terracotta (“baked earth”) is a non-vitreous ceramic fired at 600-1,000 °C.